5TH: Kula da motoci da tsarin kewayawa

Motar da tsarin kewayawa, wanda shine tushen wutar lantarkiinjin sakawa, dole ne a bincika sosai akai-akai don guje wa rushewar da ba dole ba. Waɗannan su ne mahimman abubuwan aikin:

1. Duba injin don yabo

2, Bincika ko fuse da carbon goga ga mota sun lalace (VS Motors da inverter Motors ba tare da carbon goga)

3.Duba canji don rashin aiki

4. Bincika wayoyi don lalacewa da cire haɗin

5. Duba mota, haɗa layin, tsaftace bearings (bearings) da kuma ƙara lubricating man fetur.

6. Bincika kayan aikin da suka dace, dabaran daidaitawa da bel ɗin bel a cikin tsarin tuƙi, kuma bincika ƙarar hayaniya, sako-sako ko lalacewa.

7. Take saukar da tsarin: Duba man taro na gearbox sau ɗaya a wata, kuma ƙara da bindiga mai.

Yi amfani da man shafawa 2 # MOBILUX; ko SHELL ALVANIL 2 # mai mai mai; ko WYNN mai yawan maƙasudin mai. Ko koma zuwa “Manual Umarni don Fabric Rolling down system”.

6TH: Daidaita, rikodi da shigar da sauri

1. Gudun gudu nainjian saita, haddace da sarrafawa ta inverter

2. Don yin saitin, danna A don ci gaba da lambobi ɗaya da V don ja da baya ɗaya lambobi, Danna> don matsar da matsayi ɗaya zuwa dama.Bayan an gama saitin, danna DATA don yin rikodin, na'urar zata yi aiki bisa ga saurin umarni.

3,Lokacin injiyana gudana, don Allah kar a danna maɓalli daban-daban na inverter.

4. Don amfani da kuma kula da inverter, don Allah karanta "Inverter da Umarni Manual" daki-daki.

7TH: Bututun mai

1. Hazo irin auto oiler

A, Haɗa tashar iska ta kwampreshin iska zuwa mashigar iska na injector mai atomatik tare da bututun filastik, kuma ƙara man allura zuwa tankin mai na auto.

B, Daidaita da iska kwampreso da mai wadata, da man taro ya kamata ya zama ya fi girma a lokacin da na'ura ne sabon, don haka kamar yadda ba su gurbata masana'anta.

C, Saka dukkan sassan bututun mai da ƙarfi, kuma lokacin da kuka fara injin, zaku iya ganin yadda mai ke gudana a cikin bututu, wato, al'ada ce.

D. A kai a kai cire najasa daga iska tace.

2. Electronic auto oiler

A, The aiki ƙarfin lantarki na lantarki auto oiler ne AC 220± 20V, 50MHZ.

B、^ Zaɓi maɓallin lokaci kuma danna sau ɗaya don matsar da firam ɗaya.

C. > Maɓallin motsi ramin mai, danna sau ɗaya don matsar da grid ɗaya, zuwa ABCD ƙungiyoyi huɗu.

3. SET/RLW Saitin aiki key, danna wannan maɓallin lokacin sake saiti, kuma danna wannan maɓallin lokacin da aka gama saitin.

4. An saita duk maɓallan saitin don danna wannan maɓallin a lokaci guda

5. AU gajeriyar hanya Danna wannan maɓallin don ƙara mai da sauri.

8TH: kofar inji

1. Daya daga cikin kofa uku nainjimai motsi ne don jujjuya masana'anta, kuma dole ne a ɗaure ƙofar kafin injin ya gudana.

2. Gate mai motsi yana sanye da na'urar firikwensin da ke tsayar da kofar nan take idan an bude ta.

9TH: Mai gano allura

1, The allura ganowa zai tsalle fita nan da nan a lokacin da saka allura karya, kuma za ta sauri aika shi zuwa ga kula da tsarin, da kuma na'urar za ta daina gudu a cikin 0.5 seconds.

2. Lokacin da allura ta karye, mai gano allura yana fitar da walƙiya na haske.

3. Bayan maye gurbin sabuwar allura, da fatan za a danna mai karya allura don sake saita shi.

10TH: Na'urar ajiyar yarn

1. The yarn ajiya na'urar taka mai kyau rawa a ciyar da yarn ainji.

2. Lokacin da wani yarn ya karye, hasken ja na na'urar ajiyar yarn zai yi walƙiya kuma injin zai daina aiki da sauri a cikin 0.5 seconds.

3. Akwai raba da kuma wadanda ba raba yarn ajiya na'urorin. Na'urar ma'ajiyar yarn ɗin daban tana da kama, wanda babban ɗigon ɗigon ruwa ke motsa shi zuwa ƙasa ta ƙasan ja. Lokacin mayar da yarn, kula da ko an shigar da kama.

4. Lokacin da aka sami lint ya tara a cikin na'urar ajiyar yarn, ya kamata a tsaftace shi cikin lokaci.

11ST: Radar mai tara kura

1, The aiki ƙarfin lantarki na radar kura tara ne AC220V.

2. Mai radar kura zai juya tare da na'ura a kowane bangare don cire lint lokacin da aka fara na'ura, kuma zai daina juyawa lokacin da injin ya tsaya.

3. Mai tara ƙura na radar ba zai juya lokacin da aka danna maɓallin ba.

4, Domin radar kura tara, da reversing akwatin a saman tsakiyar shaft sanye take da carbon goge, da ƙura a cikin reversing akwatin ya kamata a tsabtace da wani lantarki kowane kwata.

Sanarwa:

Dole ne a daidaita tashin hankalin bel daidai da diamita na dabaran ciyarwar yarn kowane lokaci.

12TH: Duban Tsara

A, Yi amfani da ma'auni don bincika tazarar da ke tsakanin silinda na allura da triangle na ƙananan da'irar. Matsakaicin tazara tsakanin 0.2mm-0.30mm.

B, The rata tsakanin allura Silinda da triangle na babba farantin. Matsakaicin tazara tsakanin 0.2mm-0.30mm.

Maye gurbin sinker:

Idan mai sintiri yana buƙatar maye gurbin, an fi son a juya mai nutsewa da hannu zuwa matsayi mai daraja. Sake sukurori, cire abin yanke farantin na sama, sannan kawai maye gurbin tsohon sinker.

C,Maye gurbin allura:

Matsayi tsakanin latch ɗin allura da na'urar ganowa, matsayin mai ganowa ya kamata ya kasance a cikin matsayi na al'ada kuma allurar sakawa na iya wucewa cikin sumul ba tare da tsayawa ba saboda taɓa na'urar binciken.Zaɓin allura da shigar da shi ya kamata a yi taka tsantsan, don juya na'ura da hannu zuwa bakin bakin, sannan cire allurar da ba ta dace ba daga ƙasa kuma maye gurbin shi da sabon allura.

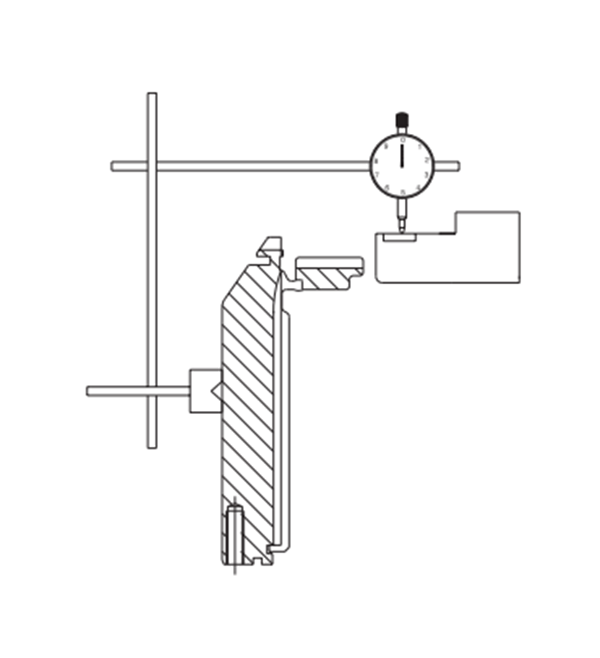

D. Daidaita matsayi na radial na sinker

Ya kamata a daidaita sinker zuwa matsayin P, sa'an nan kuma ya kamata a gyara alamar bugun kira a matsayin O.

Sake dunƙule A don tura matsayin radial na triangle na sama gaba ko baya. Bincika matsayi na sinker tare da ma'aunin bugun kira.

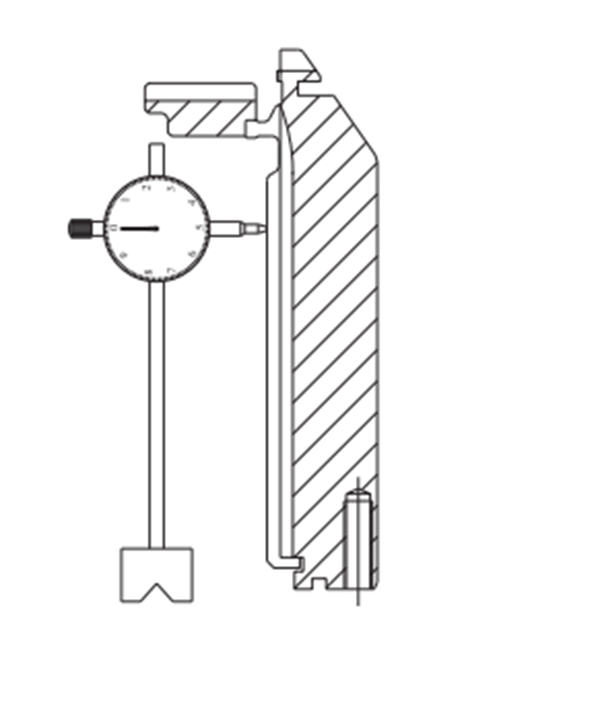

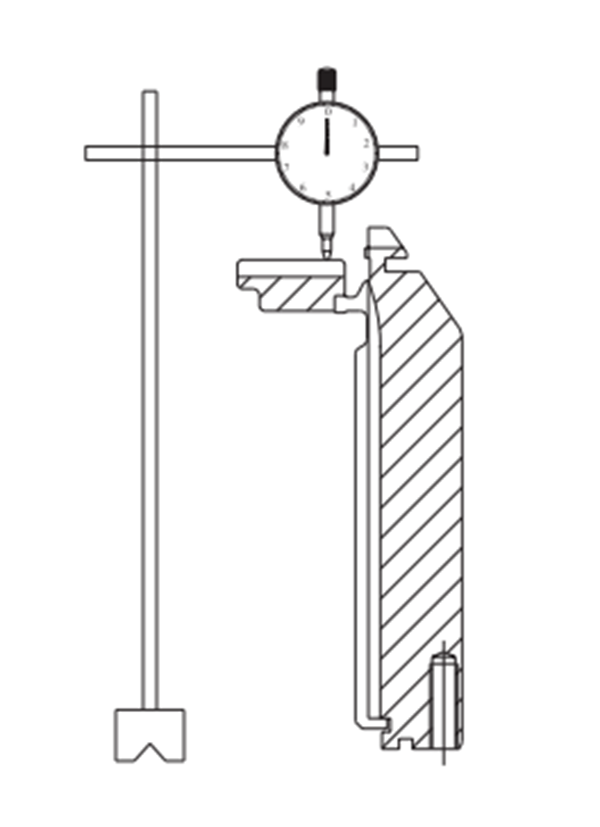

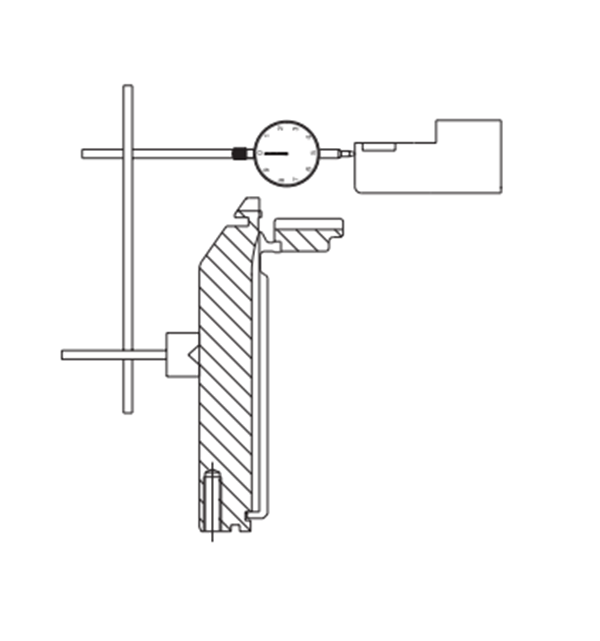

E. Daidaita tsayin allura

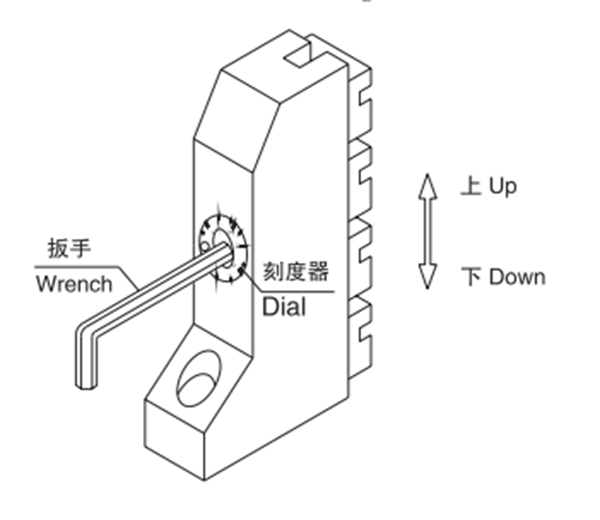

a, Yi amfani da maƙarƙashiyar Allen 6 mm don daidaita ma'auni.

b, Lokacin da maƙallan ke juya agogon agogo, tsayin allurar saka yana raguwa; lokacin da ya juya counterclockwise, tsayin allurar saka ya tashi.

13RD: Matsayin Fasaha

An bincika samfuran kamfanin sosai, an daidaita su kuma an gwada su. Na'ura mai zafi mai zafi ba ta da ƙasa da sa'o'i 48, kuma ƙirar saƙa mai sauri ba ta da ƙasa da catties 8. An kafa fayil ɗin bayanai na injin, kuma ana iya kera shi bisa ga buƙatun mai amfani.

1. Silinda concentricity (roundness)

misali ≤0.05mm

2. Silinda Parallelism

misali ≤0.05mm

3. Daidaituwar farantin sama

misali ≤0.05mm

5. Coaxial (roundness) na babban farantin

misali ≤0.05mm

14TH:Tsarin sakawa

Injin saka da'iraza a iya rarraba ta nau'in allura, adadin silinda, daidaitawar silinda da motsin allura.

Theinjin sakawa madauwariya ƙunshi na'urar ciyar da zare, na'urar saƙa, na'urar juye-juye da hanyar watsawa. Ayyukan hanyar ciyar da zaren shine kwance zaren daga bobbin a kai shi zuwa wurin saƙa, wanda ya kasu kashi uku: nau'i mara kyau, nau'i mai kyau da nau'in ajiya. Ciyarwar yarn mara kyau ita ce zana zaren daga bobbin ta hanyar tashin hankali kuma aika shi zuwa yankin saƙa wanda yake da sauƙi a cikin tsari da kuma ciyar da yarn ɗin bai dace ba. Ciyarwar yarn mai kyau ita ce isar da zaren rayayye zuwa yankin saka a cikin saurin layi akai akai. Abubuwan da ake amfani da su sune ciyar da yarn iri ɗaya da ƙananan sauye-sauye na tashin hankali, wanda ke taimakawa wajen inganta ingancin yadudduka. Ciyarwar nau'in ajiya na nau'in zaren shine a kwance zaren daga bobbin zuwa bobbin ajiya na zaren ta hanyar jujjuyawar bobbin ajiyar yarn, kuma ana zaro yarn daga bobbin ajiyar yarn ta hanyar tashin hankali sannan ya shiga wurin saka. Tun lokacin da aka adana yarn a kan bobbin ajiya na ɗan gajeren lokaci na shakatawa, an cire shi daga madaidaicin yarn ɗin ajiya na bobbin, don haka zai iya kawar da tashin hankali na yarn da ke haifar da nau'i na nau'i daban-daban na bobbin da maɓalli daban-daban.

Ayyukan tsarin sakawa shine saƙa zaren a cikin masana'anta na silinda ta hanyar aikin na'urar sakawa. Naúrar ɗinkin da za ta iya samar da zaren ciyar da kanta cikin madauki ana kiransa tsarin saka, wanda aka fi sani da “Feeder”. Injunan saka da'ira gabaɗaya an sanye su da Feeders da yawa.

Tsarin saƙa ya haɗa da alluran sakawa, jagororin yarn, sinkers, danna faranti na ƙarfe, silinda da cams, da dai sauransu. Ana sanya alluran sakawa a kan silinda. Akwai nau'i biyu na Silinda, Rotary da gyarawa. A cikin injin madauwari na latch, lokacin da silinda mai jujjuya ta kawo allurar latch a cikin ramin Silinda zuwa kafaffen cam, cam ɗin yana tura butt ɗin allurar don motsa allurar ɗin ya saƙar zaren cikin madauki. Wannan hanya tana da amfani don ƙara saurin abin hawa kuma ana amfani da shi sosai. Lokacin da aka gyara silinda, allurar latch ɗin tana tura ta da cam ɗin da ke juyawa kewaye da silinda don samar da madauki. Wannan hanya ta dace don canza matsayin cam yayin aiki, amma saurin abin hawa yana da ɗan jinkiri. Allura tana jujjuyawa tare da silinda, kuma mai sintiri yana motsa zaren, ta yadda zaren da allura su yi motsi na dangi don samar da madauki.

15TH: Gyaran Fil ɗin Aluminum Ciyar da Yarn

Micro daidaitawa: Lokacin daidaita diamita na yarn ciyar dabaran, sassauta da fastening na goro a saman aluminum disc.

Yi la'akari da cewa lokacin da murfin saman ya juya, ya kamata a ajiye shi a kwance kamar yadda zai yiwu, in ba haka ba bel ɗin hakori zai faɗo daga tsagi na dabaran ciyar da yarn.

Bugu da kari, yayin daidaita diamita na dabaran ciyar da yarn, ya kamata a daidaita tashin hankali na bel ɗin haƙori na tashin hankali. Daidaita tashin hankali belt.

Idan tashin hankali na bel ɗin hakori ya yi sako-sako da yawa, dabaran ciyar da zaren da bel ɗin haƙori za su zame, a ƙarshe zai haifar da karyewar zaren da ƙura.

Daidaita tashin hankali kamar haka:

Matakan daidaitawa: Sauke dunƙule dunƙule na firam ɗin tashin hankali, daidaita matsayin dabaran watsawa don canza tashin hankali na bel ɗin hakori.

Lura: Duk lokacin da aka canza diamita na dabaran ciyarwar yarn, dole ne a daidaita tashin hankali na bel ɗin hakori daidai.

16TH: Fabric take down system

Ayyukan masana'anta na sauke kayan aikin shine yin amfani da nau'i-nau'i na jujjuyawar na'urori masu juyayi don manne mayafin launin toka, zana sabon masana'anta daga wurin da aka kafa madauki, a juyar da shi zuwa wani nau'i na fakiti. Dangane da yanayin jujjuyawar abin abin nadi, masana'antar zazzage injin ya kasu kashi biyu: nau'in tsaka-tsaki da nau'in ci gaba. An raba miƙewa na ɗan lokaci zuwa madaidaiciyar madaidaiciya da mara kyau. Nadi mai ja yana jujjuyawa a wani kusurwa a tazara na yau da kullun. Idan adadin juyawa ba shi da alaƙa da tashin hankali na masana'anta launin toka, ana kiran shi madaidaiciya madaidaiciya, yayin da idan adadin jujjuya ya iyakance ta hanyar tashin hankali na masana'anta launin toka, ana kiran shi Negative stretching. A cikin injin ci gaba da ja, abin nadi yana jujjuyawa a kan saurin gudu, don haka yana da kyau ja.

A wasuinjin sakawa madauwari, Hakanan an shigar da tsarin zaɓin allura don saƙa ƙira da ƙungiyar launi. Ana adana bayanan ƙirar da aka ƙera a cikin wata na'ura, sa'an nan kuma an sanya alluran sakawa a cikin aiki bisa ga wata hanya ta hanyar watsawa.

Fitowar ka'idar injin saka madauwari ya dogara da dalilai kamar saurin, ma'auni, diamita, mai ciyarwa, sigogin tsarin masana'anta da ingancin yarn, wanda za'a iya bayyana shi ta hanyar fitarwa = saurin Silinda (Rev / maki) × Silinda diamita (cm / 2.54) × adadin feeder. Na'urar saka madauwari tana da mafi girman daidaitawa ga sarrafa yadudduka, kuma tana iya saƙa ƙira da launuka iri-iri, kuma tana iya saƙa guntun riga guda ɗaya da aka gama. Injin yana da tsari mai sauƙi, yana da sauƙin aiki, yana da babban fitarwa, kuma yana mamaye ƙaramin yanki. Ya ƙunshi babban kaso a cikin injunan sakawa kuma ana amfani da shi sosai wajen kera tufafin ciki da na waje. Duk da haka, ba za a iya ƙara yawan ko rage yawan alluran aiki a cikin silinda don canza nisa na zane mai launin toka ba, yanke amfani da zane mai launin toka na silinda yana da girma.

Lokacin aikawa: Oktoba-23-2023