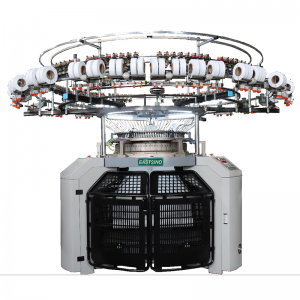

Kamara don injin saka madauwari

Da farko, don masana'anta daban-daban da buƙatun masana'anta don zaɓar abin da ya dacekama lankwasa. Domin mai zane na masana'anta style bin daban-daban, daban-daban girmamawa, don haka dakama aiki surface kwana zai zama daban-daban.

Saboda allura ko nutsewa dakama Alamar dogon lokaci na gogayya mai saurin zamewa, makiyin tsari na mutum a lokaci guda kuma dole ne su jure tasirin mitoci, don hakakama zaɓi na tikitin ƙasa Cr12MoV, kayan yana da kyau hardenability, nakasar wuta, nakasar wuta, taurin wuta, ƙarfi, tauri sun fi dacewa dakama's bukatun.kama quenching taurin gaba ɗaya shine HRC63.5±1. kama taurin ya yi yawa ko kuma ya yi ƙasa da ƙasa zai sami sakamako mara kyau.

kama lankwasa surface roughness yana da matukar muhimmanci, shi da gaske kayyade kokama yana da kyau kuma mai dorewa.kama lankwasa surface roughness, shi ne ta wurin aiki kayan aiki, kayan aiki, sarrafa fasaha, yankan da sauran m abubuwa na yanke shawara (disu masana'antun.kama farashin yayi ƙasa sosai, yawanci a cikin wannan hanyar haɗin don yin labarai).kama aiki mai lankwasa da rashin ƙarfi gabaɗaya an ƙaddara shi azaman Ra≤0.8 ku. aiki surface roughness ba a yi da kyau zai haifar da nika allura diddige, buga allura, wani kusurwa wurin dumama da sauran mamaki.

Bugu da kari, amma kuma kula dakama Matsayin rami, hanya mai mahimmanci, siffar da lanƙwasa matsayi na dangi da daidaito, waɗannan kulawa ba su iya haifar da mummunan tasiri.

![[Kwafi] Biyu Jersey 4/6 Launuka Stripe madauwari na'ura](https://cdn.globalso.com/eastinoknittingmachine/xacacac-2-300x300.jpg)